SECTOR 1 - MANUFACTURING UNIT

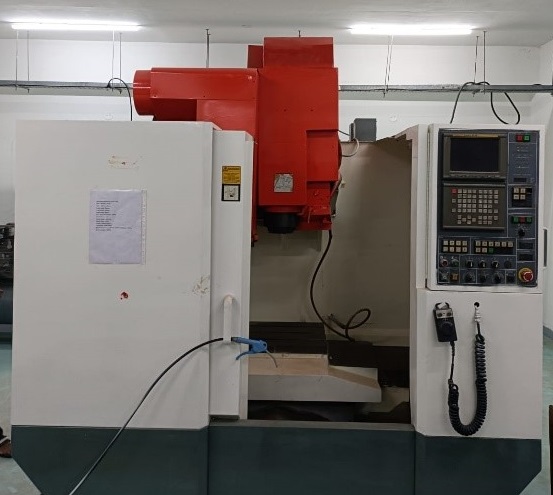

CNC VERTICAL MILLING MACHINE

VMC Machine are chiefly used to turn raw blocks of metal like aluminium, steel and other metal components. The most common industrial applications of these are cutting, drilling, shaping and molding of any kind, with high accuracy and precision, even with multiple procedures and complex shapes.

CNC WIRE CUTTING EDM MACHINE

EDM is used mainly by the molding, making, tool, and die industries. EDM helps cut exotic and high precision material components accurately at lower costs. It can be applied to all electrically conducting metals. Complex die sections and various molds can be produced accurately and precisely at a very lower cost in comparison to conventional drilling/milling machines.

RADIAL DRILLING MACHINE

Drilling Machine is to make circular holes on the components with the help of Drill bits. But, the purpose of the Radial Drilling Machine is used to drill the holes in the given radial distance and this will be used, when the component size is large in terms of height.

CNC TURNING CENTER

CNC turning is a manufacturing process that involves holding bars of material in a chuck and rotating them while feeding a tool to the piece to remove material until the desired shape is achieved.

TOOL AND CUTTER GRINDER

A Tool and Cutter Grinder is used to sharpen milling cutters and tool bits along with a host of other cutting tools.

BENCH GRINDING MACHINE

Essentially, bench grinders are just tools for spinning grindstones, and these grindstones are for gently shaping metal. They're commonly used for getting blunt tools back to full sharpness, but they're not a one-stop-shop for instantly putting an edge on a tool. When using a cutting blade, the edge gradually dulls.

GEAR HOBBING MACHINE

Gear hobbing is the process of generating gear teeth with a helical cutting tool, or hob. The gear blank and hob rotate continuously until all gear teeth are cut into the blank. The speed of this process makes it ideal for large production runs.

CENTER LATHE MACHINE

The Centre Lathe is used to manufacture cylindrical shapes from a range of materials including; steels and plastics. Many of the components that go together to make an engine work have been manufactured using lathes.

HORIZONTAL MILLING MACHINE

The horizontal milling machine is a type of machine tool with a spindle parallel to the worktable, used to process various planes, inclined planes, and grooves with cylindrical milling cutters, disc cutters, angle cutters, forming cutters, end mills, and more tools.

POLY-CRYSTALLINE PV MODULES

Polycrystalline solar panels are a type of photovoltaic panel that converts sunlight into electricity. These panels are made up of multiple smaller silicon crystals. It is less expensive and less space-efficient. When polycrystalline solar panels are properly designed and installed, it will be a reliable and cost-effective source of clean energy.

INDUSTRIAL GRADE 6 AXIS (OR) ABOVE ROBOTIC ARM

A 6-axis robotic arm is a type of robot that is capable of moving in six degrees of freedom. This means that the robot can move in three-dimensional space and can rotate around three different axes. The ability to move in six axes makes a robotic arm more versatile and able to perform a wider range of tasks. 6-axis robotic arms are commonly used in manufacturing, assembly, and material handling applications where precision and flexibility are required.